Email Us

215.230.9325 or 877.230.9325

Email Us

215.230.9325

Pond Aerator & Lake Aeration FAQ’s

Frequently Asked Questions

When should a pond water fountain be used as a pond aerator or lake aerator?

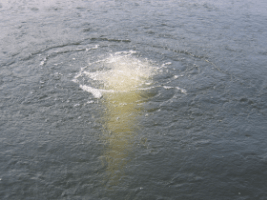

Overall, water fountains (also known as pond water fountains, pond fountains, floating fountains, pond aerators, lake water fountains, and lake fountains) are primarily installed as water features to enhance the appearance of ponds and lakes. Water fountains may increase water circulation in smaller, shallower ponds. Under such conditions, water fountains may increase dissolved oxygen concentrations and possibly decrease the amount of phytoplankton (free-floating microscopic aquatic plants or algae). Water transparency (clarity) may even improve if phytoplankton levels drop significantly. However, if water quality improvements are the primary objective, a diffused-air (AirLift aeration system) is recommended and a water fountain may be installed as a water feature.

What’s the best type of pond air compressor for pond and lake aeration?

There are several types of air compressors (air blowers, linear, diaphragm, rotary vane, piston and rotary screw) known by various names (aerator pump, pond bubbler, pond aeration pump, diffuser pump, water aerator, septic aerator, ) that are commonly used as pond aerators and lake aerators. Of these types, piston air compressors are the best all around choice for ponds and smaller lakes.

Piston air compressors are highly durable, very reliable and extremely cost-effective when it comes to producing high airflow volumes under pressure. This is why our dual piston air compressors can be placed in any water depth up to 35 feet. In many instances, smaller diameter air supply tubing, which connects the air compressor to the air diffuser, can be used in many installations. Smaller diameter air supply tubing is less expensive and much easier to install. Conversely, linear, diaphragm and rotary vane compressors should only be used in shallower ponds and lakes (generally less than 10 feet in depth) because they are not capable of producing high air pressures and may eventually burn-up the motor. In addition, these other types of air compressors typically require larger diameter, heavier air supply tubing to account for air pressure drops. Larger diameter, heavier air supply tubing is more expensive and more labor intensive to install.

On a per horsepower (HP) basis, dual piston air compressors simply out perform standard rotary vane air compressors. For example, a standard ¾ HP (0.75 HP) rotary vane air compressor produces airflow of 8 scfm (standard cubic feet per minute) at open flow (0 psi) and 6.8 scfm at 10 psi (pounds per square inch). Conversely, standard dual piston air compressors (0.66 HP) produce airflows of 9.8 scfm at open flow and 9.0 scfm at 10 psi! This simply means that you obtain more air for less money and have the option to use smaller lighter tubing due to the higher pressure rating of the piston compressors.

Lastly, high air pressure allows our AirPod air diffusers to be easily cleaned from the shoreline. Simply allow the compressed air from the compressor to flex the EPDM tube air diffuser to dislodge any mineral deposits, algae and sediments from its surface. Unfortunately, other air compressors (linear, diaphragm, rotary vane) cannot deliver sufficient airflow under pressure to adequately inflate (flex) the EPDM tube air diffuser for proper cleaning. For these other aeration systems, the pond or lake owner must launch a boat; pull up the entire air diffuser base to the surface of the pond or lake; scrape off the debris; and rinse the air diffusers with a concentrated acid solution. This is exactly the reason the manufacturers of rotary vane compressor aeration systems insist that you run them year-round – basically doubling the operating costs.

Our air diffusers are properly sized for our compressors. We have had the experience of replacing many disc diffuser membranes (air diffuser, pond bubbler, fine bubble diffuser, diffuser sticks, pond diffuser, compressor diffuser, bubble diffuser, aerator diffuser, water diffuser, disc diffuser, submersible aerator, fish tank aerator, membrane diffuser) that have blown off their mounting bases simply because they cannot handle the air diffluser flow of the compressor. To date, we have not had a single tube diffuser failure with the one exception of a muskrat chewing through a membrane. Once the tube diffuser is located on the bottom of your pond you will not need to retrieve it for many years. This fact alone will save you over a thousand dollars over the life of your pond aerator system – and alot of aggravation.

Is there an advantage of using air diffusers with fewer, larger EPDM membranes?

Air diffusers with fewer, larger EPDM rubber membranes typically will have fewer problems. This applies to air diffusers with EPDM disc and tube membranes. Our standard AirPod air diffuser uses a single, large EPDM rubber membrane tube diffuser. Our standard AirPod XL air diffuser uses two, large EPDM rubber membrane tube diffusers. The EPDM rubber membranes are designed to handle the total airflow of the air compressors, which means the membranes will not tear away from the tube (unlike EPDM rubber discs). In addition, one of our EPDM rubber membrane tube diffuser is 2 ½ times bigger than two standard 9-inch EPDM disc diffusers. Overall, our AirPod air diffusers are simply the most durable, reliable and efficient air diffusers on the market today! With its unique design, our AirPod air diffusers will not get snagged by boat anchors and are the only EPDM air diffusers that can be ran over with a truck, installed in a pond or lake and remain fully operational for the next five or more years!

Will pond aeration improve my water quality?

Yes. The overall extent of improvement will largely depend upon how eutrophic your pond or lake originally was prior to aeration. Aeration is used to artificially circulate ponds and lakes in order to increase dissolved oxygen concentrations in deeper waters. Ponds and lakes that thermally stratify during the summer will completely mix when aerated. This will result in nearly uniform water temperatures from the surface to the bottom of the pond or lake.

One potential benefit of aeration is the reduction of iron and manganese problems for drinking water supplies. Iron and manganese can be released from lake sediments under anoxic conditions in stratified ponds and lakes and artificial circulation via aeration can reduce this phenomenon. Another potential benefit of aeration is to improve water<>transparency by reducing the amount of phytoplankton. Lastly, aeration may even reduce the amount of accumulated muck in ponds and lakes. This may occur by oxygenating deeper waters near the sediments. Under such conditions, bacteria organic matter much more quickly.

Phytoplankton reductions resulting from aeration are based upon a series of complex physical, chemical and biological reactions. Some of the current theories are as follows:

- Increased dissolved oxygen concentrations in deeper pond and lake waters will decrease the release of phosphorus (and metals) from sediments. Lower phosphorus concentrations provide less food for algae growth.

- When the water column is mixed, phytoplankton are pushed into the deeper water. This may result in lower growth and reproduction rates for the phytoplankton due to lower rates of photosynthesis in darker waters.

- Zooplankton (barely visible to the naked eye, tiny aquatic animals that feed upon algae or phytoplankton) are pushed into deeper waters due to pond and lake mixing. In darker waters, they are less vulnerable to sight feeding fish such as, juvenile bass, bluegill and crappie. Under such conditions, zooplankton survival rates are expected to increase, which in turn translates into higher predation rates on phytoplankton (algae).

- Rapid circulation of carbon dioxide-enriched bottom waters with surface waters and contact with the atmosphere may increase the carbon dioxide content and lower the pH of the surface waters. This encourages the growth of less noxious green algae as opposed to blue-green algae.

Why are EPDM rubber air tube diffusers better than airstones?

The newest, most innovative technology in pond and lake aeration is the use of EPDM rubber air diffusers. EPDM rubber air diffusers are commonly used in aerating and treating municipal and industrial wastes. EPDM rubber air diffusers produce very fine bubbles which provide better water mixing in pond and lakes. They are less prone to clog up and are essentially maintenance free when compared to air stones and micro-porous media air diffusers. The manufacturers of pond and lake aeration systems equipped with air stones and micro-porous media air diffusers recommend cleaning their air diffusers at least once per year. This means launching a boat; pulling up the entire air diffuser base to the surface of the pond or lake; scraping off the debris; and rinsing the air diffusers with a concentrated acid solution. In addition, these same manufacturers typically recommend operating their aeration systems year round to avoid clogging up their air diffusers. Year round aeration may be necessary for ponds and lakes in the southern states with longer growing seasons, but this is generally not the case for ponds and lakes in the northern states. We often recommend aerating northern ponds and lakes from April through September or mid-October. Winter aeration is only recommended if the water body has a history of having fishkills when ice forms. Conversely, EPDM rubber diffusers will not clog when aeration systems are shut down for extended periods of time. This is because the tiny slits in the rubber membrane completely close and subsequently cannot clog. There are two types of EPDM rubber membranes – round discs and tubes. We use EPDM rubber tube air diffusers, which are simply much more durable than the round discs. Overall, the EPDM round disc rubber membranes are more prone to failure where the rubber discs frequently tear away from its plastic housing.

Will my piston pond air compressor always restart after a power outage?

No unless your aeration systems is equipped with some type of mechanism to release the high air pressure from your air supply lines. If this air pressure is not released, your air compressor will attempt and likely fail to restart when electric power returns. Under such condition, you can severely damage the motor of your air compressor and of course, your aeration system can be down for an extended period of time resulting in poorer pond or lake water quality and even a fish kill may occur. In contrast, our dual piston air compressors are outfitted with our proprietary SureStart™ technology. This allows automatic restart of the air compressor under full pressure during any power outage (blackouts or brownouts) without damaging the air compressor motor. Our AirSaver Timer™ allows the air compressor to be turned on/off at different time intervals (adjustable up to 10-hours). This provides the pond or lake owner with another option to further reduce the annual operating costs if so desired.

How loud is an AirLift pond aerator system?

Our standard AirLift aeration systems are equipped with dual piston air compressors. The noise levels of our dual air compressors are approximately 55 decibels at 3 feet. As a reference a person whispering is about 40 decibels. A TV set at 3 feet away is 60 decibels. Ear plugs should be worn at 85 decibels. Amplified rock music is about 110 decibels and the threshold of pain for human beings is 134 decibels. Sound and the way that humans perceive sound is quite a complicated subject. An increase of 10 decibels is perceived to be approximately twice as loud. An important rule of thumb is that a 6 decibels increase/decrease in sound takes place when your distance is halved/doubled. So if you’re standing 3 feet away at one of our standard dual piston compressors and then move to a distance of 6 feet – you will notice a decrease in noise of 6 decibels. Based upon the above, if you are standing 25 feet from one of our dual piston air compressors, it will sound like someone whispering (less than 40 decibels). Unless some special precautions are taken, it is very difficult to sound proof a cabinet (enclosure) and provide adequate ventilation to keep the compressors cool. Our standard systems are designed to give a 5 degree Fahrenheit temperature rise within the cabinet. This temperature rise must be limited or else serious degradation to the life of the air compressors will result. If less noise is required, especially true with our larger custom systems, the enclosure must be designed to limit the amount of noise produced from within the enclosure itself. Special consideration must be given to the airflow requirements in order to maximize the life of the air compressor while dissipating sound. An example of not using any special techniques would be to imagine yourself standing outside of your neighbor’s house and there is a screaming child inside (by the way this is in no way indicative of our personal lives). If you crack the front door open, the sound dramatically increases. If you completely open the door, there is very little difference than when the door was only slightly ajar. This is the same situation that occurs when other manufacturers try to “sound proof” their enclosures by lining the inside of their cabinets with insulation and other materials, but fail to use any other special techniques. Under such conditions, the sound of the air compressors simply escapes through the louvers of the enclosure – just like the screaming child’s voice traveling through the partially opened front door!

What is a Diagnostic – Feasibility Pond Study or Lake Study?

A Phase I Diagnostic – Feasibility Pond Study or Lake Study is a two-part study designed to determine the current conditions of a pond or lake and its surrounding watershed and to develop a lake and watershed management plan. The diagnostic phase of the study generally involves collecting, analyzing and interpreting pond or lake and watershed data. The feasibility phase extends from the diagnostic work and its purpose is to identify and evaluate all plausible pond or lake and watershed best management practices to restore and/or protect pond or lake water quality. Therefore, it cannot be overemphasized that the collection, analysis and interpretation of pond or lake data and watershed data are a critical step when evaluating and selecting pond or lake and watershed best management practices for future implementation.

What are hydrologic and pollutant budgets for ponds and lakes?

A hydrologic budget is a detailed water balance for a pond or lake. The major water inputs and outputs to and from the pond or lake are determined. In addition, if you know the water volume of the pond or lake, the hydraulic retention time (HRT) of the pond or lake can be determined. Overall, the hydrologic budget has a large effect on the internal mixing and circulation properties of ponds and lakes, as well as on the settling rate of sediments. The HRT can have a huge impact on the rate and magnitude of algae blooms and therefore plays an important role in defining the chemical, physical and biological properties of a pond or lake. Pollutant budgets generally represent the amount of nutrients (phosphorus and nitrogen) and sediments annually transported from the watershed and internally from in-pond or in-lake sediments into the pond or lake. Information obtained from pollutant budgets often provides insight on the causes of various pond or lake water quality problems.

What is a Certified Lake Manager?

The North American Lake Management Society (NALMS), one of the premier organizations when it comes to pond and lake management and restoration, maintains a list of Certified Lake Managers (CLM). Certified Lake Managers (CLM) are those individuals who have exceptional training and experience in lake management, thereby establishing themselves as valuable participants in the mission of NALMS.

A lake manager or professional is a person who is directly involved in the comprehensive management of a pond, lake, reservoir or other bodies of water and its watershed and makes decisions which affect the quality and uses of the body of water. This person will be primarily responsible for implementing appropriate measures and/or for making recommendations to the governing management body.

Are solar pond aerator and windmill aerator systems more effective than electric?

Oh wouldn’t the world be a beautiful place! Unfortunately, solar aeration systems (solar pond aeration systems, solar pond aerator or solar aerator) and windmill aeration systems (windmill pond aeration systems, windmill pond aerators or windmill aerators) typically use very small air compressors to generate air bubbles or very small motors to turn impellers to mix the pond and lake waters. Therefore, solar pond aerator and windmill pond aerator systems should only be used for very small ponds (less than 0.25 acres) where there is no chance of bringing electricity to the pond or lake. If there is any possibility of using electricity as the source of power, it is highly recommended to install an electric powered pond aerator or lake aerator system like an AirLift™ aeration system. If it is not cost effective to run electricity to the pond or lake, another option is to order a custom AirLift™ aeration system. The air compressor cabinet can be located over 1,000 feet away from the pond or lake and a remote valve box can be located at the water’s edge to control the airflow to the AirPod™ air diffusers.

In general, pond aeration and lake aeration systems fail when they are undersized and unfortunately only partially mix a pond or lake. This is what typically occurs on cloudy days with solar pond aerator and on windless days with windmill pond aerator systems. Many pond and lake owners complain each year about summer time fishkills when the above conditions persist for several consecutive days. In addition, partial mixing of a pond or lake will often increase the amount of nutrients released from pond and lake sediments resulting in even larger algae blooms.

The manufacturers of solar aeration systems (solar pond aerators, or solar aerators) and windmill aeration systems (windmill pond aeration, windmill pond aerator or windmill aerators) often boast of great savings when operating their aeration systems. What they often forget to tell you is that solar pond aeration and windmill aeration systems may cost three to five times more for the same amount of air produced by our standard AirLift™ pond aeration and lake aeration systems. These systems are often grossly undersized to provide proper aeration for your pond or lake. These same manufacturers also fail to inform their customers that their aeration systems are not capable of operating 24 hours a day – 7 days a week as needed. Lastly, there are some additional hidden costs for these aeration systems. For example, the costly batteries of the solar pond aeration systems will need to be routinely maintained and replaced and the windmills and their components will require periodic maintenance.

When solar power aeration or wind powered aeration systems become much more efficient and cost effective, we would absolutely love to run our pond aeration systems from either of the free gifts that mother-nature provides. We’re keeping our fingers crossed that someday technology will allow these alternative energy sources to operate our air compressors efficiently! Until that time comes, the only cost-effective way to properly aerate ponds, lakes, reservoirs and marinas is by using electricity.

Why Aerate Your Pond?

Learn more about why you should aerate your pond or lake

How AirLift Aerators Work

Learn how AirLift pond aerators & lake aeration systems work

The AirLift Advantage

Learn why AirLift pond & lake aerators are the best in the industry

AirPod Air Diffusers

Learn why our AirPod air diffusers are the most durable & reliable

Physical Address

1519 Broad Street

Perkasie, PA 18944

Payments & Mailing Address:

PO Box 605

Doylestown, PA 18901

Copyright © 2023 Hydro Logic - All Rights Reserved.